EMC preliminary test has become important to reduce cost and time in electronic product development . MR2150 launch ed by MICRONIX corp. is a precompliance test system for conducted EMI.

This paper presents significance of EMC precompliance test, and practically sufficient measurement accuracy of MR2150 in comparison with a compliance test system.

Significance of EMC precompliance test

Meaning of EMC precompliance test in product development

Electronic products are required to be compatible with EMC regulations , and have to be tested at a formal EMC test site. But the site use fee is not inexpensive , and there are many cases hard to make reservations of the site. Therefore, prior EMC design and test are important to shorten the site using time and reduce cost . This prior design is called "EMC front-loading design", and a representative example of this prior test has been known as "EMC precompliance test". EMC events in product development flow are shown in F ig. 1-1.

Major objective of the front-loading design is to minimize the overall cost in product development by devoting deliberately man-hours in the early stage of the design phase. Because design modification in the early design stage is more inexpensive and effective than that in the final design stage.

Similarly to the front - loading design, the pr ior test is useful to minimize the cost. The prior test , that can be called "front-loading test", can increase the possibility of avoiding countermeasures in the final test stage at a formal EMC test site.

Fig.1-1 EMC events in product development flow

Comparison of precomliance test and other preliminary test

Various EMC evaluation/test solutions related to front-loading or precompliance have been proposed in the market. It is good for customers to have many choices, but that can be difficult to select most suitable one for a product to be tested. If correlation with result of compliance test is still important, it is most reasonable to select a precompliance test system such as MR2150.

There might be a case that result of other test system such as near field scanner or TEM(GTEM) cell is correlated with result of the compliance test. But tha t would generally consists in very limited case. In the case, high EMC skill and understanding of all the factors that affect the results would be required. On the other hand, a precompliance test system ha s great advantage to be able to directly judge OK or NG to the test result.

When launching EMC evaluation/test environment, it is recommended to select a precompliance test system such as MR2150 in the first and other EMC solutions suitable for a product to be tested in the second to reduce the risk of failure in the selection.

EMI measurement accuracy of MR2150

EMI measurement accuracy of spectrum/signal analyzer MSA series

To check EMI measurement accuracy of spectrum/signal analyzer easily, there is a way to input CW (continuous sine wave). Then , it is ideal that QP (quasi peak) and AV (average) are equal to PK(peak) in magnitude . CISPR16 requires less than ±2dB deviations of QP and AV against PK.

Fig.2-1 shows errors of QP and AV measured by spectrum/signal analyzer MSA series (RBW:9kHz, sweep time:30sec, reference level:80dBμV) entered CW (150kHz, 45dBμV) from a signal generator. Measurement accuracy of MSA series is equivalent to EMI compliance receivers. Incidentally, entered 45dBμV is near EMI limit line to be needed higher measurement accuracy. Also, measurement frequency is 150kHz in a low band that measurement accuracy of most spectrum analyzers including MSA series decreases slightly by an effect of zero frequency peak.

Fig. 2-1 EMI measurement accuracy of MSA series

EMI test of sample EUT (switching power supply)

A sample of below EUT was tested by MR2150 in a non-shielded laboratory and a compliance system at a formal EMC test site, respectively.

- EUT:Switchin pawer supply

- Working condition:AC230V, and max. current controlled by an electronic load

- EMIstandard:VCCI class B(frewuency range of 150kHz to 30MHz)

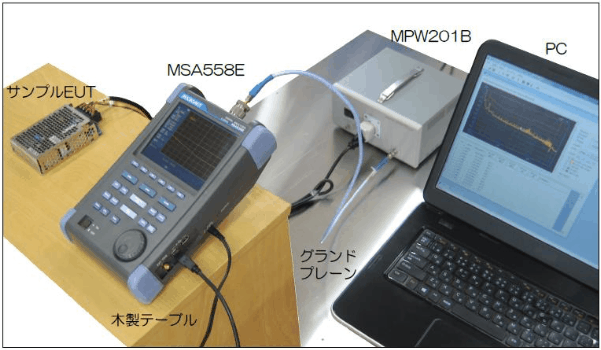

Fig. 2-2 and Table 2-1 show MR2150 test scene (image) and conditions, respectively.

Fig. 2-2 MR2150 test scene (image)

Table 2-1 Measurement conditions of MR2150

| Items | Test conditions |

|---|---|

| Range | 150kHz to 30MHz |

| RBW | 9kHz |

| Sweep time | 30s(QV, AV) |

| REF level | 80dBμV |

| Place | in a non-shielded lab.(*) |

| Ground plane size | 0.63m x 1.15m (CISPR16:>[2m x 2m]) |

| Distance between EUT and LISN | 0.8m (CISPR16:>0.8m) |

| Distance between EUT and ground plane | 0.4m (CISPR16:>0.4m) |

*There was no noise that affected the EMI measurement result.

In the test with MR2150, the size of used ground plane was smaller than 2m x 2m required by CISPR16, since it was difficult to secure a space in the lab. It is important to follow the standards as much as possible, but we believe that it is better to give priority to some degree of ease in many cases that are expedient for the purpose of the precompliance test.

Fig. 2-3 shows EMI test results of MR2150 and a compliance system.

Fig. 2-3 Comparison between test results of MR2150 and a compliance system

EMI measurement error at maximum noise peak is shown in Fig.2-4. The differences of QP and AV between two systems are only within ±3 dB or ±4dB. In an EMC formal test, variation of measurement repeatability can be 5 or 6 dB due to slight differences in the setting. MR2150 works with very practical accuracy of measurement as precompliance test system.

Fig.2-4 The differences of QP and AV at the noise peak between the two system

Fig.2-5 shows a result of measurement of noise floor in MR2150. A non-stationary noise appears in the part of the frequency, but it was fully confirmed that there was no noise to affect the EMI test result.

Fig.2-5 Noise floor measured by MR2150

A dditionally, to avoid effects caused by the difference in the measurement environment, EMI test with MR2150 in a formal EMC test site was carried out, and the test error was less than 2.0dB

2-3. Appropriate method of measurement by MR2150

It is meaningful that the reference level in above measurement with MR2150 is 80dB V.

Fig.2-6 shows EMI test results by changing the reference level.

Fig.2-6 Change in the spectrum by the reference level

Reducing the reference level extends measurement dynamic range. However, when the reference level is too low, spurious noise can appear like fig.2-6(c) because of saturation in spectrum analyzer. In formal EMC test , such a problem is unlikely to occur, s ince pre-selector filters spurious. It is important to understand useful method optimizing the reference level or using an appropriate filter to use MR2150 properly.

Conclusions

Precompliance test system MR2150 for conducted EMI plays an important role in order to reduce the cost and time in product development.

MR2150 works with very practical accuracy of measurement because measurement errors of QP and AV at the noise peak are only within ±3 dB or ±4 dB .

Products introduction

Please feel free to contact us.

If you want to verify 5G, customize a radio wave shield box, or need product repair, please do not hesitate to contact us about any small matter.